See picture gallery below.

Join us for Bruno’s next Thurs-Sat wood firings:

September 15th-17th; Oct. 20-22nd; Dec. 15-17th

Read about Wood Firing Basics.

Read about Bruno’s First Firing

Read about Bruno’s First Unloading

From June 4, 2015 until August 3, 2016 we worked on the wood kiln that would be Bruno. Fourteen months of planning, meetings, gatherings, idea swapping, kilnstarter information going out, donations coming in and all the drawings and coordination plus hiring Jordan Becker to build Bruno.

The beginning was a phone call from Bruno Laverdiere and his generous offer of his entire gas kiln. With the brick and metal as the seed we progressed to plans for a Bourry Box wood kiln. Because Bruno’s offer started our wood kiln journey we decided to name our kiln after him.

The potter who is the behind the scenes and the engine that sparked Bruno is Patrick Durkin. Patrick continues to be supportive and we are always hopeful he’ll be standing in our doorway one day soon.

At Northeast Ceramic Supply/Monroe ClayWorks (NEC/MCW) we thought a Kilnstarter would help us fund the building of Bruno plus broaden and cement our already fabulous clay community.

Eighty-two potters, sculptors and friends came together to donate their money and time as an investment in this community. I cannot say thank you often enough or tell everyone how grateful we are for all eighty-two of you fabulous people.

On July 28th of this year, Jordan told me he would be finishing Bruno on August 4th. The next day, July 29th, I sent all Bruno donors an email saying our first firing would be August 10 – 12th. What an incredible outpouring of help, supportive messages and hugs came out of that email message. Everyone who wanted to and who had cone 10 work came and glazed or left work on shelves at NEC/MCW for Bruno. We had an amazing line up of volunteers to wad, load, entertain and stoke for our first firing.

Potters and sculptors came to NEC/MCW with boxes of their work. Their work was measured, glazed if they chose to glaze it, then put on shelves to await wadding and loading. The week before our firing, as the work was coming in, potters signed up for “jobs”. We had seven people sign up to wad and load Bruno. Fortunately, Susan Nowogrodzki and Rachel Garrison had previously wadded work for wood firings so they instructed the other wadders.

With all the preparation done days before (preparation included making and bisquing drawbaskets, making cone packs, kiln washing and putting the bagwall in place and mixing ten gallons of kiln wash and five gallons of wadding) and pots lined up awaiting wadding and loading all I had to do was give the wadders a shelf post and ask them to wad pots that would fit under that post.

Wadding was a learning experience for some with the consideration of how each piece should/could be wadded. White glue, towels and wadding (60% EPK, 40% Alumina Hydrate) were at hand as everyone sat around two benches to work. Shells were wadded under a few pieces. Most pieces were wadded to sit vertically. It was a graceful scene with each person choosing pots to wad, rolling appropriate sized wads then dipping them in glue and attaching them to the foot of the pot. There was conversation, laughter, questions and lots of sharing of our adventure in wood firing. I could feel the excitement, apprehension and anticipation.

As pieces were wadded they were brought outside to Bruno. Susan was making wads outside beside Bruno. These wads were placed between all posts and shelves. Four wads top and bottom between each post and shelf. As I looked over each pot, I decided how it could sit on the shelf, and which pot face that would get the direct flame and the rear that would hopefully get ash and heatwork. I was nervous and tried to see each pot as a rock in a stream of flame. I loaded up the bottom shelves with medium sized work.

Susan and I worked together fitting three shelves on the wadded posts. The second layer of shelves was for shorter work and I asked Susan to help load them with me. We worked side by side for the next two layers of shelves. Bruce Ross and David Smythe began working with Susan and me and were soon loading pieces alongside us.

Our loading of pots and sculptures had to be balanced with placement of cone packs and drawbaskets. With the aid of a measuring tape we loaded and we made several trial rolls of the cart into the ware chamber to check placement of cone packs and that there wasn’t any piece of work too close to the edge. The top shelf was loaded with our tallest work and then we realized that we’d done it ~ we’d finished loading and it was time to roll the cart into Bruno for firing.

I cannot thank the potters who helped in loading the kiln often enough. Barbara Costanzo, Rachel Garrison, Mary LaFleur, Harriet Hauser, Bruce Ross, David Smythe, Judy Cid and Susan Nowogrodzki all did a fabulous job.

In the midst of loading Bruno Erika Sanger brought us a beautiful bear kiln god she had just sculpted. The bear is in a sitting position and has a bowl in its lap. What a treat to have a brown bear as our first kiln god. After cooing over Erika’s bear I turned around to see both Susan and Rachel finishing up three more kiln gods!! Our Bruno first firing was graced by four creative kiln gods.

Loading Bruno went very smoothly and quickly. We’d loaded and pushed the ware cart into the chamber by 2:30 p.m. In addition to loading the ware cart we also put pots on the bagwall, in front of the bagwall, in front of the flues and into the passive damper in the chimney. The last bit of loading was in the Zone of Death (ZOD). After finishing all other loading I climbed into the firebox and potters handed me wadding and about seven pots to be tumblestacked into the ZOD.

Once Bruno was loaded it was time for The Lighting Ceremony. The Lighting Ceremony ~ We placed a tray with a large block of Himalayan salt, an ichibana vase with flowers, the bear kiln god, a lovely lidded wood fire pot and a plate of leftover pizza crusts from a pizza we’d had from lunch on Bruno. We then swept the exterior pad all around Bruno.

Our next step was to all wash our hands and collect handmade pottery mugs for each of us and a container of salt. As a group we walked around Bruno and each sprinkled salt on the kiln (for purification). Lining up with mugs in our hands we each sipped some Italian sparkling water then sprayed some of the water on the kiln. Standing beside Bruno in a group I asked for a moment of silence to meditate for a good firing. Our next step was to place a large, knotty log in the firebox and light a fire. We used a bit of paper and a propane torch and (ta~da) Bruno was lit.

In the time it took me to walk around the kiln to the chimney there was already a wisp of smoke coming out of the passive damper. Bruno’s first firing had begun. With big grins and warm hugs we started this new venture together. Bruce was our first fire tender. He carefully made sure the small fire didn’t go out and kept it burning at 121 degrees F. for the first hour.

A firing log was kept and reflects the increase in temperature over the next 37 hours.

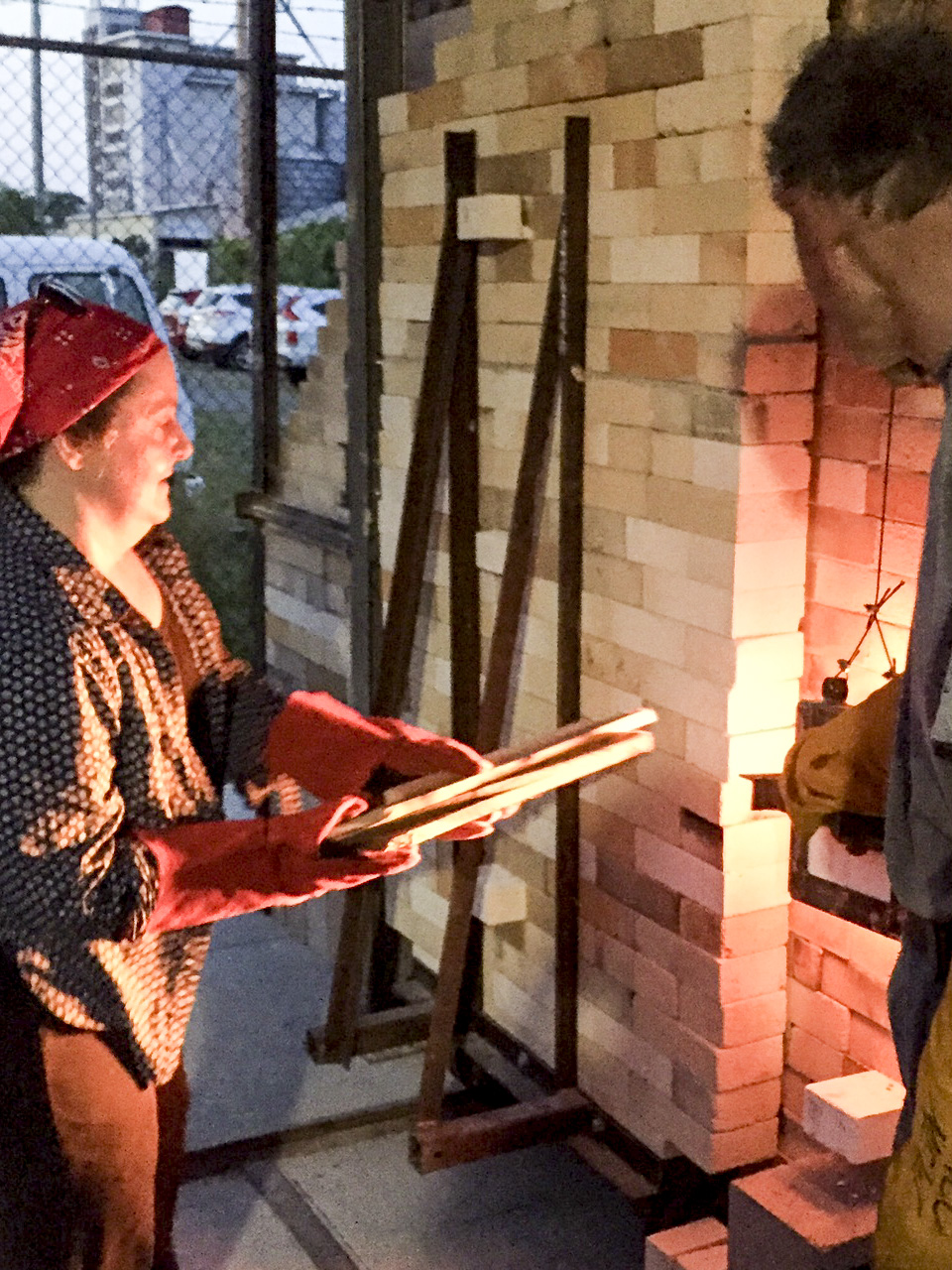

From 2:45 p.m. Wednesday afternoon until 4:15 a.m. Friday morning twenty-four potters participated in our first wood firing. Our firing log reflects all 37 hours of the firing but doesn’t record the care and enthusiasm of each person who came to help fire Bruno.

Casseroles, sweets, juice, beer, bagels, popsicles, pastries, pasta salad, deli sandwiches, Super oxidant berry smoothies and lots of bottled water are just some of the sustenance potters brought to feed and nourish us all. It was a generous outpouring of support.

There were so many smiles and hugs and words of excitement. It seems everyone felt that this was the beginning of our wood firing journey and that our bonds would only deepen as a clay community.

After our “Lighting Ceremony” some people needed to leave. Others of us settled into the chairs in front of Bruno to talk and cheer each other on. A close eye was kept on the pyrometer as we wanted to slowly raise the temperature inside Bruno to 300 degrees F. and then stay at that temperature for twelve hours ~ until 6:00 a.m. Thursday morning.

From the moment we lit Bruno there were potters visiting, talking and giving their warm support to the firing. About 8:00 p.m. Wednesday evening, everyone had left and I was alone with Bruno. It is such an easy chore to keep a fire at 300 degrees F. It is like a campfire with only the need for a bit of wood every thirty minutes or so.

At 8:30 p.m. I put two small logs in the firebox and climbed into my hammock. Dennis had chosen to put my hammock between one of the back posts of the kiln shed and a gate post. Because the night was fairly clear I could see many stars and it was a cool and peaceful night. Lying there I had a timer set for thirty minutes so I could relax and enjoy the evening. As I lay there I felt calm but a bit edgy as I realized the firing of hundreds of pieces of work inside Bruno were on my shoulders. Within a few minutes of ruminating on these thoughts and emotions I saw a shooting star and felt the firing would go well as long as we put our hearts (and backs) into it.

Each half hour I’d climb out of my hammock to check the pyrometer and put a few pieces of wood on the fire. I was content with how steady the temperature was reading on the pyrometer. A couple of hours later I saw headlights at our main gate and knew that friend and potter, Colleen O’Sullivan, had come by to tend the fire. More hugs, talk of encouragement and excitement and then Colleen shooed me inside to sleep for a few hours.

My “bed” was a camping mattress just inside the door and about twenty feet from Bruno. As I lay down I heard Colleen begin to play her tin whistle. I was lulled to sleep with beautiful Irish music. Four hours later my eyes popped open and I felt refreshed. Colleen had kept Bruno’s temperature at 300 degrees F. and it so it was at 4:00 a.m. Thursday morning that I bid farewell to Colleen.

6:00 a.m. saw Kathy Catlin pulling into the parking lot. She was excited and right on time for her 6:00 – 9:00 a.m. stoking shift. After a brief rundown on the pyrometer and temperature schedule for Bruno, Kathy began stoking to increase the heat to 375 degrees F. from 6:00 – 7:00. From 7:00 – 8:00 a.m. she increased the temperature to 525 degrees F. then from 8:00 – 9:00 a.m. another increase in temperature to 675 degrees F.

Kathy had brought herself and me a fabulous Super Oxidant Berry Smoothie that was full of fruit, veggies and packed with vitamins, minerals and antioxidants. What a treat! We talked about clay, pots, her gas kiln (Lucille) and our excitement over wood firing. It was a special three hour interlude that left me feeling emotionally stoked.

9:00 a.m. saw Susan Nowogrodzki, Bonnie Richter, Rachel Garrison and Barbara Costanzo arriving. These women potters set to work ~ what a quartet! We put a stool up near the firebox so one of us could view the pyrometer and the rest of us could stoke, eat bagels & pastries and drink coffee and water. There was an ease and flow with the four of them. They worked smoothly together and switched back and forth from stoking and quietly slipping away to bring us mugs and various treats to make us all comfortable.

Barbara Costanzo took photos and videos that seemed to capture the feel of women working together and the power of Bruno’s fire. Barbara’s photos, videos and website (MonoeClayWorks.com) have kept us all in touch with one another.

As noon time came more potters arrived and the afternoon saw David Smythe, Bruce Ross, Patti & Alan Kennedy, Theresa Zubretzky, Polly Hunt, Elizabeth Donovan, Chuck Tiley and Fred Miller arrive and set in to stoke, cart wood, bring food, treats & drink. We developed a rhythm to our stoking which went well until about 1100 degrees F. We had just switched from stoking the floor of the firebox, which is where we’d been feeding the fire since we first lit Bruno, to stoking in the two main fireboxes above the grate. I thought the switch had gone well and was surprised when we lost temperature.

We tried opening and closing different air ports and the passive damper. I fiddled with the dampers and raked the embers. The temperature continued to go down. Then someone said we should check the fireboxes ~ we opened one firebox door and saw that we needed wood!! Ah, a first firing ~ when we learn basics! We laughed, joked and stoked!!

More people came by and some (Mary Shaw and Kathy Paulsen) tried their hands at stoking. At one point mid-afternoon we stalled again and were grateful to have the wonderful husband and wife stoking team Patti & Alan Kennedy on hand. Alan is a volunteer fireman and so knows and understands fire. He coaxed, prodded and worked with Bruno and managed to bring about the necessary change in our stoking/raking so the temperature began to rise again.

Afternoon became evening and as some stokers left more stokers arrived. Arlene & Walt Wojtowicz, Don Orr, Joan Griffin and Stephanie Wojtowicz arrived all set to record, stoke and support us.

Walt had brought his chainsaw and began cutting up pallets. He was methodical and didn’t quit until he had a large crate full of pallet pieces. We got news that one of our night time stokers (Mary Pat Hopper) mother had fallen and had to be taken to the hospital. We missed Mary Pat and knew she’d have been there if not for a family emergency. Earlier in the day she’d come by to drop off deli sandwiches!

It was late evening by the time we realized the sound of the fire inside Bruno had different sounds that we needed to listen to. We stoked and listened then watched the pyrometer closely. Up and up it went and Bruno talked to us. We could hear the fire respond to the small logs, the large logs and especially the spit and roar of the dry pallet pieces. Walt joined the stokers as did Don Orr. The rhythm of stoking became every four minutes then every three minutes. I checked and pulled out a drawbasket when cone 4 went down. I knew it would be dry and underfired but I wanted to demonstrate the pulling of a drawbasket. Bruno will be a fantastic teaching tool.

Elizabeth Donovan and Theresa were our newest potters ~ they have never loaded and fired an electric kiln much less helped fire a fuel kiln. But here they were carting wood from the woodpile and then stoking Bruno! Elizabeth cheered us all with fruit popsicles! A delicious treat since we were firing Bruno on two of the hottest days of the summer.

As evening drew to a close, I saw Joan, Stephanie, Theresa and Walt stoking every two minutes. I was amazed to see them working like crazy yet still laughing and joking. David stepped in again to stoke and be part of their team. David had come to help earlier in the day and taken a shift stoking after which he had gone into the MCW studio and thrown pots. What a great idea! He was with us all day and through to the end of the firing yet he was able to relax, make pots, stoke, trim his pots, take another stoking shift and remain awake.

Midnight came and our stokers were down to David, Stephanie, Chuck and me. We stoked and stoked but seemed to be near stalling again. About 1:00 a.m. I had a memory of several of the wood firings I’d helped with over the past 25 years. There was just something we needed to do ~ what was it? ~ what change did we need to make to get Bruno’s temperature up and get the cones down? Cone 9 was soft. I could see the top three shelves seemed to be at the same cone level. The lowest shelf was lagging behind by about two cones. But there was something at the edge of my memory ~ ah! ~ We hadn’t really had fire leaping out ~ we didn’t have fire “in our face”.

I told David, Chuck and Stephanie that we were going to shift to a new stoking strategy. I named this strategy “rounds”. David and Chuck were one stoking team and Stephanie and I were the second stoking team. One stoking team would do four rounds while the second stoking team rested. Then the second stoking team would do four rounds while the first stoking team rested. A round consisted of one person opening one main firebox door and the other person stoking in a log. The door was quickly closed and the team then went to the second main firebox door and stoked one log. Without stopping the team stoked one arch firebox then stoked the second arch firebox. That completed one round.

After each round both stokers watched the pyrometer. Without fail, the pyrometer registered a rise in temperature ~ they watched until the pyrometer reached its highest temperature and then as the temperature began to drop they immediately began round two. After four rounds team one rested and the second team stoked four rounds.

It worked. We were able to keep the pyrometer reading between 2100 and 2280 degrees F. We did go up and over 2300 degrees F. a couple of times but the vast majority of time we kept to

2100 and 2280 degrees F. Cone 9 went over, cone 10 was soft and falling. We were making progress and we were very tired.

At 4:15 a.m. on Friday morning we stoked Bruno for the last time. We cleaned up around the kiln and watched as the pyrometer began to fall. We decided to rest for an hour and then check the embers. I crashed on my mattress, David headed to the big delivery truck to sleep and Chuck and Stephanie each curled up in chairs in front of Bruno.

At 5:30 I woke up and went outside. Stephanie woke up and she and I mudded up cracks and openings in Bruno. Chuck woke up and cleaned up the area all around Bruno. David woke up and came over as we all sat in chairs and discussed who was awake enough to drive home. We sat there as the sun came up. Everyone except me decided they could drive home. I crashed on my mattress . At 8:00 a.m. I was awakened by Dennis quietly saying “Hey sleepyhead”. He was checking to make sure all went well and that I was still breathing!

For all my words about the generous support of potters and friends, I must add that Dennis was there every step of the way. He guided and provided for Bruno. There would be no Bruno or wood firing without Dennis and his hard work.

For all of our clay family I am grateful and I am humbled by your spirit, support and friendship. Thank you all, Barbara