The woodfiring experience is exciting and a great reason to party with our pottery friends. Come and join us for an unforgettable clay experience. Warning: Woodfiring is addictive.

Glazing must be done two days before our firing dates. We’ll wad & load the day before our firing dates.

Last November’s firing was the best firing we’ve had in Bruno ~ it was a beautiful firing! I’m proud of all our work ~ enjoy the winter and make sure you make work for Bruno. Let’s make November 2018 firing even more fantastic! Barbara

Sample schedule for a wood firing:

Wadding, Loading: Wednesday

Start the fire: Thursday

Candle Overnight*: On Thursday

Firing: On a Friday & Saturday (Saturday 12 am to 4 pm or whenever. We can always use extra help)

Unloading: The following Saturday

*Candle Overnight means a small fire will be started and kept burning overnight in the firebox. The purpose of candling is to slowly dry and moisture in the kiln, shelves, posts, wadding and our work.

The basic charge will be three times the NEC/MCW regular firing fee for electric and gas firing. There will be a firing chart at NEC/MCW which will be based on the size of your piece.

Important Information:

- Cone 10 clay must be used. BMix10 Wood is recommended but not necessary. Any cone 10 clay can be used.

- If a glaze is used it needs to be a cone 10 glaze. There are several cone 10 glazes that NEC/MCW has available for use at a cost of $1 per pot.

To name a few glazes we will have our Korean Celedon, Persimmon, Satin White, Shino, Purple Haze and Wilt’s Haystack.

You do not have to glaze your pots. We recommend putting a glaze on the inside of functional pots as a liner glaze. Many potters prefer not to glaze the outside of their work but rather let the fire and ash mark the outside of their work. Before each firing of Bruno we’ll have glazing days & times which we’ll email out to donors.

- All work/pots must be bisque fired before being loaded into Bruno.

- There is to be no wax on the bottom of our work/pots. All pieces will be placed on wadding. We will be using wadding made of alumina hydrate and kaolin which will be added to water, made into a dough-like consistency and rolled into balls.

- Slips can be used for decorating. Donors have been given three slip recipes and a sample of each. Most slips are for use on leatherhard or bone dry pieces. Some slips can be used on bisqued pieces.

We mix 2 Tablespoons dry slip mix into 1/3 Cup of water, sieve the mixture and brush on our piece. Slip consistency is like that of light cream. If you want to use another slip recipe that is fine ~ just make sure it is a slip that can endure a cone 10 firing. - Bruno has a ware chamber which will be stacked with work/pots much like an electric or fuel kiln. Work in the chamber can be glazed if you choose to glaze it. They can be placed on shells with wadding or just on wadding. Bruno also has a Zone of Death (ZOD). This is an area directly after the firebox where work/pots are tumblestacked. ZOD gets a lot of heat and ash. It is your choice whether your piece(s) go in the chamber or ZOD. There is to be no glaze on the outside of ZOD pots. All work will be stacked or tumblestacked in Bruno according to size and available stacking space.

- Cost will be based on what is allowed by your donation. The basic charge will be three times the NEC/MCW regular firing fee for electric and gas firing. There will be a firing chart at NEC/MCW which will be based on the size of your piece. You do not have to be a donor to fire your work in Bruno.

Woodfiring is a lot of work. There are eight “jobs” that need to be done and most everyone can find a job or two they can do and feel part of the Bruno Community. No one has to do a job ~ there is no requirement to work ~ you can make and bisque your work and bring it to NEC/MCW, measure it for firing cost, and it will be fired. You can be as involved as you (and your life) allows. Below are the Jobs with a brief description of each:

- Wadders ~ These people come on loading days. Wadding will be mixed up and stored in a lidded bucket. Work/pots will be on ware boards and Wadders will roll and attach wads (3 or 5) to the bottom (or side if preferred) of the pots using white glue. (4 people needed)

- Loaders ~ Potters who are experienced in loading regular glaze kilns and feel comfortable assessing direction of flame/ash. (2 people needed)

- Splitters ~ People who are comfortable and experienced splitting logs/stumps into appropriate sized slats for stoking. In addition we will need people to use an electric saw to cut up pallets. (4 people needed)

- Stokers ~ This is a crucial, enjoyable, rough and exciting job. Stokers slide wood slats/logs into the firebox. The amount of wood slats & time between stokes depends on the firing cycle. It could be three pieces of wood every eight minutes, six pieces of wood every two minutes, holding off stoking and assessing the flame. There are many variables. Keeping the heatwork climbing, ash flowing is important, exciting and variable. There will be a potter directing the firing and approximately sixteen three person crews on three hour stoking shifts. For example, on the first day of stoking there will be three people stoking 6 – 9 a.m., three at 9 – noon, three at noon – 3 p.m., three at 3 – 6 p.m., etc. all day that day and all day the next day. Stokers must wear long pants, shoes (no sandals) ~ natural fiber clothing is best. Heavy stoking gloves and protective eyewear will be provided. (16 shifts x 3 on each shift = 48 stokers needed*) *We’re confident several people will do a couple shifts stoking so we’ll most likely only need 20 people for stoking. This is the most popular job.)

- Grinders ~ This job is heavy duty clean-up after firing. All shelves and posts will need to be chiseled and ground with an electric grinder. In addition, all kiln furniture needs to be kiln washed. Grinders also have the dirty job of cleaning out the firebox, Zone of Death (ZOD) and ware chamber. (4 people needed)

- Haulers ~ Haulers move wood. We’ll have stacks of wood that will need to be moved at intervals so that stokers have a constant supply of wood. (4 people needed)

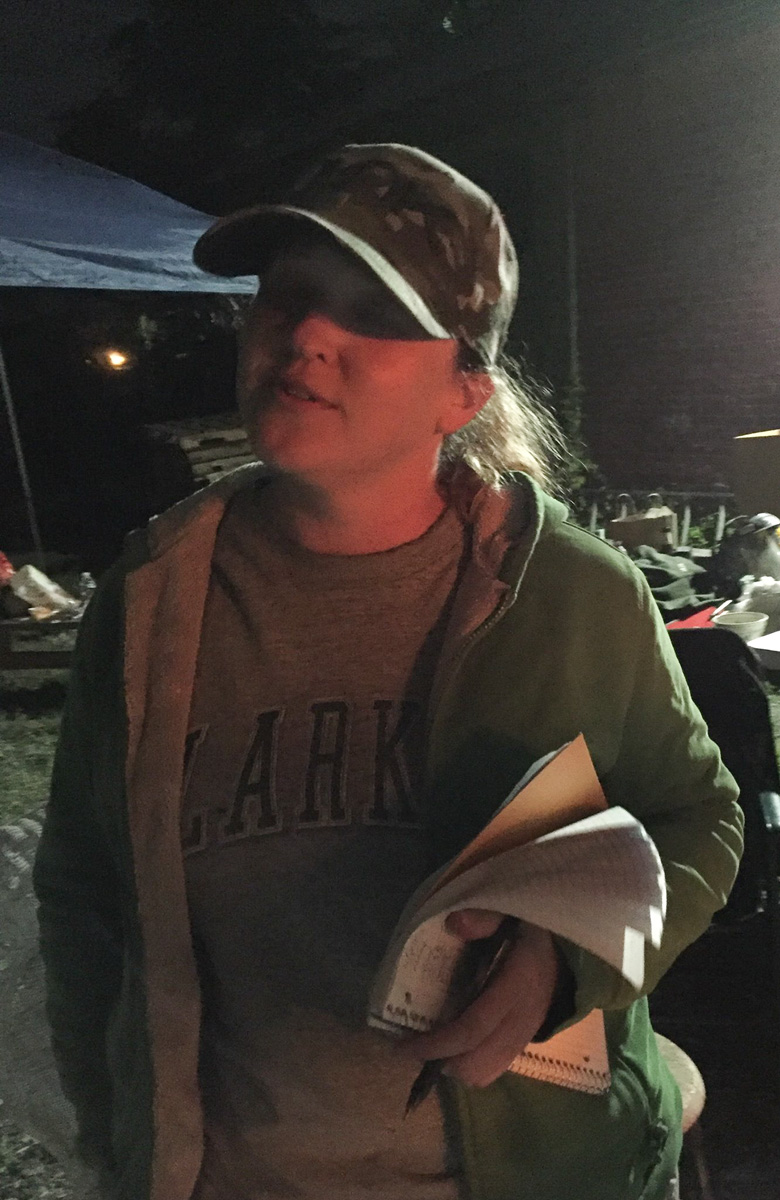

- Recorders ~ This is the only sit down job! We’ll need potters who have patience and are good at photographing and writing down details. We’ll need a recorder present for loading and unloading. (5 people needed)

- Entertainers ~ Crucial job this one!! There is no definite definition. Entertainers may be needed to bring out food and drink from the refrigerator at MCW for stokers, splitters, etc. We’ll have a supply of water that will be essential to keeping us hydrated. Entertainers might also go out for sandwiches, pizza or additional supplies. They could also set up lights and music. If you are musically inclined then please volunteer for this job! Generally this job just ensures that the stokers don’t have to leave Bruno during their stoking shift and that they are comfortable. (12 people needed)

We’re heading into an adventure ~ many firings and much learning will go under our belts as we travel this road of learning, work and excitement together. This is all about CREST.

C ommunity

R espect

E ducation

S haring

T olerance

So let’s get started!

This is about building Community ~ we have a great Clay Community and we want to keep it vital and growing.

Day is dawning and Bruno is closed up, mudded, and left to do her magic. Workers are headed home and to bed! Next Saturday we will celebrate how Bruno has kissed our pots.